Best Forklift Safety Practices

Discover the best forklift safety practices including how to do a pre-shift inspection, pointing your forks downhill when you don't have a load and uphill when you do, and more!

Today we are going to take a look at the best forklift safety practices.

We have over 40 years in the material handling industry and we would love to share our expertise and experience with you.

We'll break down the best forklift safety practices so that you can keep your workers and your equipment safe from unnecessary accidents and injuries. Let's get started.

Be safe - Learn to follow our best forklift safety practices

Best Forklift Safety Practices

There are a number of great forklift safety practices that you can follow in your workplace. Click on the following links to learn more about each one.

Perform a Forklift Inspection Before Each Shift

Only Trained Personnel Should Operate Your Forklift

Best Forklift Safe Driving Practices

Forklifts and Blind Spots

Driving on a Sloped Surface

Best Forklift Steering Practices

Best Forklift Loading Practices

How To Raise and Lower a Load Safely

Best Forklift Practices for Handling Pallets

Best Forklift Parking Practices

How to Load and Unload from Trucks, Trailers and Railways Cars

Best Forklift Practices for Using an Elevator

Perform a Forklift Inspection Before Each Shift

One of the best forklift safety practices that every operator should adopt is doing a pre-shift inspection of your forklift before you start each shift to make sure that everything is working properly and that your truck is safe to operate.

You should do both a visual and operational inspection of your forklift and if you notice anything that is wrong, do not ignore it. Tell your supervisor immediately so that the issue can be looked after.

The following video will show you the steps in the inspection; continue reading for detailed instructions about what to check.

A best forklift safety practice is to check your machine before each shift

Visual Inspection:

During your visual inspection, you should take a look at the following things:

Your working environment: Make sure that the floor you will be working on is clear of any debris and that there are no obstructions overhead. Make sure that are no objects nearby that you might hit as you drive and verify that there is a functioning fire extinguisher present.

Your engine: Check your oil, fuel, and radiator water levels if you are operating an LPG (liquid propane gas), gasoline, or diesel forklift.

.

Your battery: Make sure that your battery is fully charged and is securely in place. Check your cables for any exposed wires and make sure your battery plug connections are tight, clean, and in good condition. Make sure the vent caps are not clogged and the electrolyte levels in the cells are correct.

Your hydraulic system: Check that bolts, nuts, guards, chains, and hydraulic hose reels are tight and that they aren't damaged or missing.

Your hoses: Make sure that all of your hoses are secured and not loose, crimped, bent, worn, or rubbing.

Your tires: Check your tires for any signs of excessive wear or damage. Make sure that the tire pressure is proper if you have pneumatic tires.

Your forks: Take a look at your forks to ensure that they aren't bent, cracked, or damaged and that the positioning latches are in good condition.

In addition, check that:

Your carriage teeth are not chipped, worn, or broken

There are no damp spots around your forklift that would indicate a leak

Your chain anchor pins are in food condition and not loose or bent

During your inspection, carefully check the various parts of your forklift - Image Source: Created by Tynt22 using Adobe Photoshop. [CC BY-SA]

Operational Inspection

Your horn: Make sure it is working and loud enough to be heard over environmental noise.

Your brakes: Check that all of your brakes are working well, including your floor brakes, parking brakes, and your deadman seat brake.

Your clutch: Test out your clutch and gearshift to make sure that it shifts smoothly without jerking or jumping.

Your dashboard: Check that all of the lights on your control panel are working.

Your steering wheel: Make sure that you can move your steering wheel easily and smoothly.

Your lifting and tilting devices: Check that your lifting mechanism is moving smoothly by raising it to its maximum height and then lowering it. Then check that your tilt mechanism is working well by tilting the mast forward and backward all the way.

Your hoses and cylinders: Make sure that they are still not leaking now that you have done your preliminary inspections.

Noises: Listen for any unusual noises.

Only trained drivers should operate a forklift

Only Trained Personnel Should Operate Your Forklift

Proper training is an essential best forklift safety practice. No untrained person should be allowed to operate your forklift. You must not allow anyone to hop on for a ride either.

Make sure that your operators have successfully completed the training course appropriate to the type of forklift they are going to be using before they begin. Learn more about forklift training requirements here.

Best Forklift Safe Driving Practices

While you are operating your forklift, you should follow these best driving practices:

Do not drive too fast and decrease your speed when going around corners

Keep your hands, arms, feet, legs, head inside your truck at all times

On flat surfaces drive with your forks as low to the ground as possible and tilted backwards

Try not to make any sudden stops

Keep watching in the direction that you are travelling

Look out for wet and oil spots, loose objects, holes, rough terrain, etc.

Watch out for pedestrians and other vehicles in your vicinity

Sound your horn when going around a corner or to warn of your approach.

Forklifts and Blind Spots

Take note of any blind spots that you have in your vehicle with and without a load. If someone is crossing your route, stop driving, lower your forks to the floor and wait for the way to be clear before proceeding.

Be extra careful driving on slight inclines

Driving on a Sloped Surface

If you are operating your forklift on an incline, you should always point your forks downhill if you are not carrying a load, and point them uphill if you are carrying a load.

So this means that you will have to drive backwards down ramps when you have a load so that the load doesn’t fall off and drive and drive backwards up a ramp when you aren’t carrying a load. You should adjust the tilt of your forks to match the slope's gradient.

Never try to turn your forklift on a slope; wait until you are on level ground.

Best Forklift Steering Practices

Never turn your steering wheel sharply if you are traveling fast. Make sure to support your load by the front wheels and turn your forklift with your rear wheels.

Always follow your load capacities. If you overload your forklift, it will be very difficult to steer.

Best Forklift Loading Practices

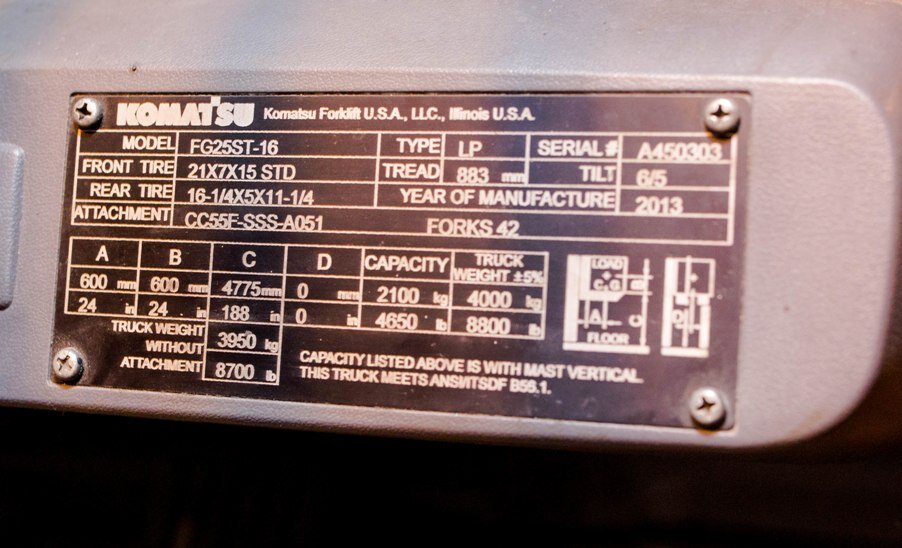

Make sure you know the manufacturer's recommended maximum load limit of your forklift and of its forks. These numbers will be on your data plate on your machine.

Never exceed these maximums. They are there for your safety and for the safety of your forklift.

Your forklift data plate will show you the maximum capacities of your lift truck

Position your load according to the recommended load centre. Never try to counterbalance an overload by adding extra weight.

You should also keep your load close to your front wheels to keep it stable. Keep your mast in an upright position and level your forks before inserting them in the pallet.

How To Raise and Lower a Load Safely

Wait until your forklift is fully stopped and braked before you attempt to lift your load. Check that you have enough overhead clearance and stay clear of any overhead power lines. Lift your load straight up and then tilt it back slightly

Stay on your forklift while your load is raised as your truck is less stable in this position. Don't let anybody walk or stand near or under the elevated load. No one should walk under a raised forklift mast even if there is no load on it.

Learn how to properly lift your load

Best Forklift Practices for Handling Pallets

Adjust your forks so that they are high enough and level to go into the pallet. Make sure they are inserted all the way underneath the load. Make sure that your forks are the right width so that the weight of your load is evenly distributed.

Best Forklift Parking Practices

When you are finished operating your forklift, park it in the approved spot. Set your brakes before leaving it and lower your forks to the floor. Put your controls in neutral and turn off your motor.

Disconnect your battery if you are operating an electric forklift or follow your propane shut-down procedures if you have a propane lift truck.

To learn more about proper battery care, click here. The following video will show you how to water your battery.

From time to time you need to water your battery

How to Load and Unload From Trucks, Trailers, and Railways Cars

Make sure you stay clear of the edges of the docks, rail cars or ramps. The edges should be clearly marked and follow these best forklift safety practices:

Do not tow or push a railway car or truck with your forklift

Do not operate your forklift inside these vehicles for extended periods unless they are properly ventilated

Ensure that the dock plate is properly secured and it can support the weight of your forklift and your load

Drive slowly and carefully over the plate and don't spin your wheels

If you need to cross a railway track, do so on a diagonal

Best Forklift Practices for Using an Elevator

Only enter an elevator if you are authorized to do so. Make sure that your forklift's weight plus the weight of your load doesn't exceed the elevator's limit. Enter the elevator squarely, put your controls in neutral, shut off your motor and put on your brakes.

For the Best Forklift Service and Inspections, Trust Wayco

Forklifts also require yearly inspections. At Wayco, we have trained personnel who meet the OHSA requirements to be able to carry out your annual forklift truck safety inspection.

Upon completion of our full vehicle inspection, we will let you know the exact condition of your equipment and once it is found to be in proper working order, we will certify your equipment for you.

You need to have this type of up-to-date inspection documentation available to show government inspectors when they come to your facility. Contact Wayco today to set up your annual inspection.

In addition to annual inspections, Wayco can also service and maintain your forklifts throughout the year to ensure they are running efficiently and safely.

“We purchased a used forklift from Wayco in January. It was extremely clean and in excellent condition when it was delivered. We have also had incredible ongoing service from the professionals at Wayco. Overall dealing with them has been an excellent experience.“

- Dons Trailer

Read More Google Reviews

Best Forklift For Your Industry

Find out the top 3 best forklift choices for manufacturing companies, large warehouses and retail stores or smaller warehouses including the walkie pallet for retail and an IC pneumatic for construction sites.

Today we are going to help you find out which is the best forklift for your industry and why.

We have over 40 years in the material handling industry and we would love to share our expertise and experience with you.

We'll list our top 3 choices for the best forklift for manufacturing companies, large warehouses and retail stores or smaller warehouses. So, let's get going.

Best Forklift for Your Industry

Find out what’s the best forklift for your industry

Best Forklift for Manufacturing Companies and Construction Sites

Many manufacturers and construction projects require forklifts to handle heavy raw materials such as lumber, steel, concrete, etc. For this reason, you will want a heavy duty forklift with high lifting capacities.

You probably will also want to look for a forklift with pneumatic tires that are designed to easily maneuver over rough or uneven surfaces found outdoors.

1. Komatsu EX50

The Komatsu EX50 has the power and the ability to work under the toughest warehouse and manufacturing applications. It features:

Diesel Powered fuel efficient engine

Pneumatic Tires

22,000 lbs / 25,000 lbs / 30,000 lbs / 35,000 lbs capacity

Wet Disc Brakes

2. EcoMaxx Stärke Heavy Duty Pneumatic Lift Truck

The EcoMaxx from Stärke is also designed to handle the rugged conditions of a construction site with:

Capacity 8,000 lbs to 22,000 lbs

Pneumatic Tires

Wide View Mast

Solid Overhead Guard

Rugged Power Train

3. Hyster H155FT

The Hyster would also make a great addition to your manufacturing or warehouse application with its:

15,500 lb. capacity

Diesel Pneumatic Forklift

2 stage mast

Dual Tire

Best Forklift for Large Warehouses

If you have a larger warehouse with elevated storage areas, you will usually require a forklift that is designed to lift to higher heights.

If you need your forklift to operate mostly inside your warehouse, then choosing one with cushion tires designed to easily move over smooth, even surfaces is also a good idea.

1. STÄRKE Cushion Forklift XVI Series

This forklift has the power to lift your heavy products high and the tires to work well on a smooth surface. It features:

Capacity 4,000 lbs to 7,700 lbs

Mast Height:270"

LPG, Gas, Diesel, Dual fuel (Gas/LPG)

2. Komatsu FR50 Series Reach Truck

A reach truck is perfect if you have tight, high spaces to reach in your warehouse. This one features:

Capacity 3,000 lbs / 3,500 lbs / 4,500 lbs

Up to 380" mast height

Single reach or double reach options

3. Stärke LiftMaxx OPS30 Electric Order Picker

Order pickers can lift workers and loads to high locations to select products. This electric model features:

Capacity 3,000 lbs

Excellent ramp and grade performance

Low center of gravity for stability

Best Forklift for Retail Stores and Smaller Warehouses

Walkies and stackers are the best forklift type for a retail or smaller warehouse setting. You can easily use walkies and stackers to move your products in your retail store out of trailers to low-level racking or out onto your retail selling floor.

These types of forklifts work well in a retail setting because they are smaller and can maneuver around the tighter spaces in a store.

They also work well because you don't need to move your product over long distances nor do you need to lift it very high.

The handles help you control the speed, steering, and lifting and because you are walking, they aren't going fast enough to be a safety issue for customers or other staff.

1. Stärke LiftMaxx 4500 lb PT45MXA Electric Walkie Pallet Truck

This walkie pallet is very easy to move around smaller spaces and has:

Capacity 4,500 lbs

On-board Charger

Maintenance Free Batteries

2. Starke LiftMaxx EMSA3300X Semi-Electric Straddle Stacker

A stacker removes the need to hand bomb products from trailers at street level. This one also includes:

Fully adjustable forks and straddle legs

Semi-electric / manual push pull functions

Powered lift

3. Pre-owned Crown PC3520-60 Walkie Pallet

If you are on a budget, why not consider purchasing a good used forklift like this one, which has:

6,000 lb. capacity

Electric 24V

48″ forks

Tips for First Time Buyers so You Get the Best Forklift

1. Purchase from a well-established supplier: Go to a local forklift supplier who has been in the industry and has a solid, established reputation in the industry. They will know what they are talking about and will be able to best advise you on your purchase.

2. Choose a company that offers great warranties: Make sure you select a forklift that comes with a great warranty. A manufacturer will back up their quality product with a warranty because they know that it is good.

3. Check out online reviews: Go online and check out the reviews of the forklift company that you are considering using and see what their previous customers have to say about them: whether they are reliable, whether their pricing is fair, and if they stand by their products.

Wayco for the Best Forklift and Warranty in the Industry

Whether you are in the market for a new or used forklift, talk to the professionals at Wayco.

Wayco offers the best warranties in the business for both new and used forklifts so you can purchase with confidence!

Our expert sales team can find the perfect model for your needs with an incredible warranty to match.

If you are looking for reliable and affordable maintenance and repairs for your forklift, Wayco has an incredible service department that is there for you 24/7 to make sure that you are always up and running. Contact us today!

“…they found just the right truck for our needs. Their repair Techs are knowledgeable and friendly and get the job done no matter what the problem is. Just want to thank Steve P, Chris and Rob for their help the past few months for keeping our production and shipping rolling.” […Read more]

- Canadian BakeInn

Best Forklift of 2019

The best Forklift of 2019 was Komatsu. Learn more about why it was #1; we've also included 3 runners up: Stärke, Clark, and Mitsubishi. Learn why they made the list too.

Today we're going to explore why Komatsu was the best forklift of 2019.

We have over 40 years in the forklift industry and we would love to share our expertise and experience with you.

In this post, we'll take a closer look at what makes Komatsu the best forklift of 2019 and we'll also look at some of the runners' up. So, let's jump on in.

komatsu was the best forklift of 2019

Best Forklift of 2019

There are so many different types of forklifts on the market made by many different manufacturers. You may find it difficult to the choose the best forklift. We'll help make your decision easier by showing you the best forklift manufacturers in the business today.

We have chosen the top companies who provide the highest quality and highest performing models. Plus, we’ll showcase a wide range of price points and models to so you can find one that meets your specific needs.

Keep in mind that all of these companies are also leaders in innovation. This means that you are going to get a vehicle that is state-of-the-art with all of the great ergonomic and efficiency features that you want in a forklift.

Forklift operators love using Komatsu forklifts

What Makes Komatsu the Best Forklift of 2019?

Out of all the forklift makers on the market, we think that Komatsu offers the best forklift and here's why:

Highly rated by customers: Komatsu gets consistent high ratings from customers. This is a huge factor in determining the best forklift. After all it is you, the customer, who will know firsthand how well the forklift operates and functions on a day to day basis.

Long History of Experience: Komatsu has been in business for almost 100 years. You can only stay in business that long if you have superior products and exceptional customer service.

Highly Durable and Reliable Products: The name Komatsu has become "synonymous with durability and reliability" in the forklift industry. That is because they have always strive to produce material handling vehicles that are state-of-the-art, durable, and well made.

Komatsu has a wide variety of products

Wide Variety of Products: Komatsu's extensive line of forklifts include specially designed models to navigate narrow spaces, environmentally friendly electric models, highly rugged and durable pneumatic diesel options and much more.

Low Cost of Operation: Komatsu forklifts are designed to be highly efficient so they can give you the the low-cost operation you need.

The following video shows just one of Komatsu's highly durable and reliable forklifts: the Komatsu FH-2 Series.

Komatsu’s FH-2 Series is perfect for construction applications

Honourable Mentions: Runners Up for Best Forklift

Stärke

Stärke is a close runner-up to Komatsu for best forklift of 2019 and for good reason.

Customers also Like Stärke Forklifts: Customers are happy with the craftsmanship of Stärke forklifts, as well as the large selection that they offer.

"The Stärke line is well-crafted and offers a large selection of equipment. With a rapidly growing dealer network they are making a strong name for themselves."

- Mike Poeltl

Wide Selection of Products: Stärke has a great selection of products to suit whatever material handling need you have.

Whether you need electric forklifts for indoor applications, pneumatic forklifts for rough terrain and outdoor use, or stackers, reach trucks, order pickers or walkie rider pallets for smaller spaces, Stärke has a great choice of models and weight capacities.

The following video will give you a great overview of the Stärke equipment lineup.

Stärke has an extensive equipment line-up

4. Mitsubishi

Mitsubishi is better known for its cars as it is relatively new in the forklift industry. However, they have used their expertise in manufacturing quality vehicles to help them make one of the best forklifts available.

Environmentally Friendly: One of Mitsubishi's greatest strengths is its ability to produce highly energy-efficient and eco-conscious forklift equipment.

Innovation: Mitsubishi is also known for its innovation as evidenced by its FD70 Heavy Duty model. This is the first of its kind that will allow you to lift more than 10,000 pounds.

Customer Satisfaction: According to customers Mitsubishi forklifts have great handling and are comfortable to operate. The following video is a customer review of the Mitsubishi forklifts that they use in their company, Steere Enterprises.

Mitsubishi forklifts are easy to operate

Clark Forklifts

Clark Forklifts celebrated 100 years in the material handling business in 2017 and they have built more than one million forklifts. Here are some of the reasons why they too make our list for the best forklifts.

Consistently Meet Customer and Regulatory Requirements: Clark was the first forklift manufacturer in the world to be certified with ISO 9001. This is the international standard for a quality management system.

It is used by organizations to show their "ability to consistently provide products and services to meet customer and regulatory requirements and to demonstrate continuous improvement."

Broad Product Line: Clark features a broad product line with five distinctive major lines of forklifts, including electric, pneumatic, cushion, narrow-aisle, and walkie pallet stackers.

Committed to Safety: Clark forklifts are designed with your safety in mind. The following video shows a number of their safety features.

Clark forklifts have great safety features

You Can Trust Wayco for the Best Forklift on the Market

Whether you are looking for a new or used forklift, you can trust Wayco to sell you the best! We sell the best new forklifts including Komatsu and Stärke, as well as the best used forklifts from the top manufacturers.

We fully inspect and certify every used forklift before we sell it to you and we offer incredible warranties, so you can be sure you are getting a high quality vehicle. We'll accept your old model as a trade in - and we also offer financing.

We are a full service forklift dealership. In addition to new and used forklift sales, we also offer:

Highly trained technicians to service all of your lift trucks

Service on all makes and models

Forklift preventative maintenance programs to ensure your trucks are running as efficiently as possible and are compliant with current safety regulations

A full line of forklift parts for any make or model and safety equipment

Contact us for all your forklift needs.

![Forklift_dealers[1].jpg](https://images.squarespace-cdn.com/content/v1/5bf6c41789c1727b3aa7157a/1574968412524-0VM7F1G1IX2NPAHR2YBZ/Forklift_dealers%5B1%5D.jpg)