Best Forklift Safety Practices

Discover the best forklift safety practices including how to do a pre-shift inspection, pointing your forks downhill when you don't have a load and uphill when you do, and more!

Today we are going to take a look at the best forklift safety practices.

We have over 40 years in the material handling industry and we would love to share our expertise and experience with you.

We'll break down the best forklift safety practices so that you can keep your workers and your equipment safe from unnecessary accidents and injuries. Let's get started.

Be safe - Learn to follow our best forklift safety practices

Best Forklift Safety Practices

There are a number of great forklift safety practices that you can follow in your workplace. Click on the following links to learn more about each one.

Perform a Forklift Inspection Before Each Shift

Only Trained Personnel Should Operate Your Forklift

Best Forklift Safe Driving Practices

Forklifts and Blind Spots

Driving on a Sloped Surface

Best Forklift Steering Practices

Best Forklift Loading Practices

How To Raise and Lower a Load Safely

Best Forklift Practices for Handling Pallets

Best Forklift Parking Practices

How to Load and Unload from Trucks, Trailers and Railways Cars

Best Forklift Practices for Using an Elevator

Perform a Forklift Inspection Before Each Shift

One of the best forklift safety practices that every operator should adopt is doing a pre-shift inspection of your forklift before you start each shift to make sure that everything is working properly and that your truck is safe to operate.

You should do both a visual and operational inspection of your forklift and if you notice anything that is wrong, do not ignore it. Tell your supervisor immediately so that the issue can be looked after.

The following video will show you the steps in the inspection; continue reading for detailed instructions about what to check.

A best forklift safety practice is to check your machine before each shift

Visual Inspection:

During your visual inspection, you should take a look at the following things:

Your working environment: Make sure that the floor you will be working on is clear of any debris and that there are no obstructions overhead. Make sure that are no objects nearby that you might hit as you drive and verify that there is a functioning fire extinguisher present.

Your engine: Check your oil, fuel, and radiator water levels if you are operating an LPG (liquid propane gas), gasoline, or diesel forklift.

.

Your battery: Make sure that your battery is fully charged and is securely in place. Check your cables for any exposed wires and make sure your battery plug connections are tight, clean, and in good condition. Make sure the vent caps are not clogged and the electrolyte levels in the cells are correct.

Your hydraulic system: Check that bolts, nuts, guards, chains, and hydraulic hose reels are tight and that they aren't damaged or missing.

Your hoses: Make sure that all of your hoses are secured and not loose, crimped, bent, worn, or rubbing.

Your tires: Check your tires for any signs of excessive wear or damage. Make sure that the tire pressure is proper if you have pneumatic tires.

Your forks: Take a look at your forks to ensure that they aren't bent, cracked, or damaged and that the positioning latches are in good condition.

In addition, check that:

Your carriage teeth are not chipped, worn, or broken

There are no damp spots around your forklift that would indicate a leak

Your chain anchor pins are in food condition and not loose or bent

During your inspection, carefully check the various parts of your forklift - Image Source: Created by Tynt22 using Adobe Photoshop. [CC BY-SA]

Operational Inspection

Your horn: Make sure it is working and loud enough to be heard over environmental noise.

Your brakes: Check that all of your brakes are working well, including your floor brakes, parking brakes, and your deadman seat brake.

Your clutch: Test out your clutch and gearshift to make sure that it shifts smoothly without jerking or jumping.

Your dashboard: Check that all of the lights on your control panel are working.

Your steering wheel: Make sure that you can move your steering wheel easily and smoothly.

Your lifting and tilting devices: Check that your lifting mechanism is moving smoothly by raising it to its maximum height and then lowering it. Then check that your tilt mechanism is working well by tilting the mast forward and backward all the way.

Your hoses and cylinders: Make sure that they are still not leaking now that you have done your preliminary inspections.

Noises: Listen for any unusual noises.

Only trained drivers should operate a forklift

Only Trained Personnel Should Operate Your Forklift

Proper training is an essential best forklift safety practice. No untrained person should be allowed to operate your forklift. You must not allow anyone to hop on for a ride either.

Make sure that your operators have successfully completed the training course appropriate to the type of forklift they are going to be using before they begin. Learn more about forklift training requirements here.

Best Forklift Safe Driving Practices

While you are operating your forklift, you should follow these best driving practices:

Do not drive too fast and decrease your speed when going around corners

Keep your hands, arms, feet, legs, head inside your truck at all times

On flat surfaces drive with your forks as low to the ground as possible and tilted backwards

Try not to make any sudden stops

Keep watching in the direction that you are travelling

Look out for wet and oil spots, loose objects, holes, rough terrain, etc.

Watch out for pedestrians and other vehicles in your vicinity

Sound your horn when going around a corner or to warn of your approach.

Forklifts and Blind Spots

Take note of any blind spots that you have in your vehicle with and without a load. If someone is crossing your route, stop driving, lower your forks to the floor and wait for the way to be clear before proceeding.

Be extra careful driving on slight inclines

Driving on a Sloped Surface

If you are operating your forklift on an incline, you should always point your forks downhill if you are not carrying a load, and point them uphill if you are carrying a load.

So this means that you will have to drive backwards down ramps when you have a load so that the load doesn’t fall off and drive and drive backwards up a ramp when you aren’t carrying a load. You should adjust the tilt of your forks to match the slope's gradient.

Never try to turn your forklift on a slope; wait until you are on level ground.

Best Forklift Steering Practices

Never turn your steering wheel sharply if you are traveling fast. Make sure to support your load by the front wheels and turn your forklift with your rear wheels.

Always follow your load capacities. If you overload your forklift, it will be very difficult to steer.

Best Forklift Loading Practices

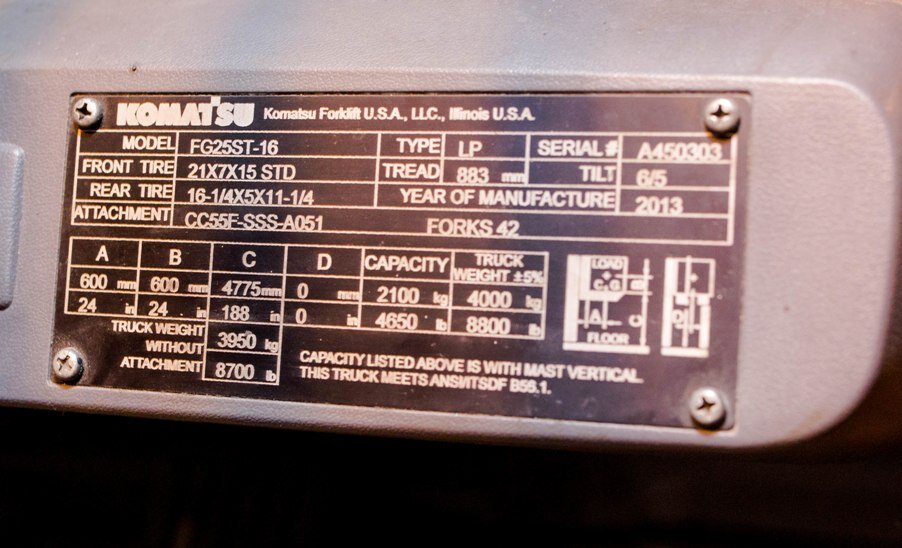

Make sure you know the manufacturer's recommended maximum load limit of your forklift and of its forks. These numbers will be on your data plate on your machine.

Never exceed these maximums. They are there for your safety and for the safety of your forklift.

Your forklift data plate will show you the maximum capacities of your lift truck

Position your load according to the recommended load centre. Never try to counterbalance an overload by adding extra weight.

You should also keep your load close to your front wheels to keep it stable. Keep your mast in an upright position and level your forks before inserting them in the pallet.

How To Raise and Lower a Load Safely

Wait until your forklift is fully stopped and braked before you attempt to lift your load. Check that you have enough overhead clearance and stay clear of any overhead power lines. Lift your load straight up and then tilt it back slightly

Stay on your forklift while your load is raised as your truck is less stable in this position. Don't let anybody walk or stand near or under the elevated load. No one should walk under a raised forklift mast even if there is no load on it.

Learn how to properly lift your load

Best Forklift Practices for Handling Pallets

Adjust your forks so that they are high enough and level to go into the pallet. Make sure they are inserted all the way underneath the load. Make sure that your forks are the right width so that the weight of your load is evenly distributed.

Best Forklift Parking Practices

When you are finished operating your forklift, park it in the approved spot. Set your brakes before leaving it and lower your forks to the floor. Put your controls in neutral and turn off your motor.

Disconnect your battery if you are operating an electric forklift or follow your propane shut-down procedures if you have a propane lift truck.

To learn more about proper battery care, click here. The following video will show you how to water your battery.

From time to time you need to water your battery

How to Load and Unload From Trucks, Trailers, and Railways Cars

Make sure you stay clear of the edges of the docks, rail cars or ramps. The edges should be clearly marked and follow these best forklift safety practices:

Do not tow or push a railway car or truck with your forklift

Do not operate your forklift inside these vehicles for extended periods unless they are properly ventilated

Ensure that the dock plate is properly secured and it can support the weight of your forklift and your load

Drive slowly and carefully over the plate and don't spin your wheels

If you need to cross a railway track, do so on a diagonal

Best Forklift Practices for Using an Elevator

Only enter an elevator if you are authorized to do so. Make sure that your forklift's weight plus the weight of your load doesn't exceed the elevator's limit. Enter the elevator squarely, put your controls in neutral, shut off your motor and put on your brakes.

For the Best Forklift Service and Inspections, Trust Wayco

Forklifts also require yearly inspections. At Wayco, we have trained personnel who meet the OHSA requirements to be able to carry out your annual forklift truck safety inspection.

Upon completion of our full vehicle inspection, we will let you know the exact condition of your equipment and once it is found to be in proper working order, we will certify your equipment for you.

You need to have this type of up-to-date inspection documentation available to show government inspectors when they come to your facility. Contact Wayco today to set up your annual inspection.

In addition to annual inspections, Wayco can also service and maintain your forklifts throughout the year to ensure they are running efficiently and safely.

“We purchased a used forklift from Wayco in January. It was extremely clean and in excellent condition when it was delivered. We have also had incredible ongoing service from the professionals at Wayco. Overall dealing with them has been an excellent experience.“

- Dons Trailer

Read More Google Reviews

![Forklift_dealers[1].jpg](https://images.squarespace-cdn.com/content/v1/5bf6c41789c1727b3aa7157a/1574968412524-0VM7F1G1IX2NPAHR2YBZ/Forklift_dealers%5B1%5D.jpg)